A twin extruder is a pretty efficient device used in plastic, polymer, meals, and chemical processing industries. In contrast to single extruders, dual extruders use parallel screws that rotate together, permitting higher mixing, better output, and unique manage over cloth processing. Due to their versatility and consistency, twin extruders are extensively desired for worrying packages.

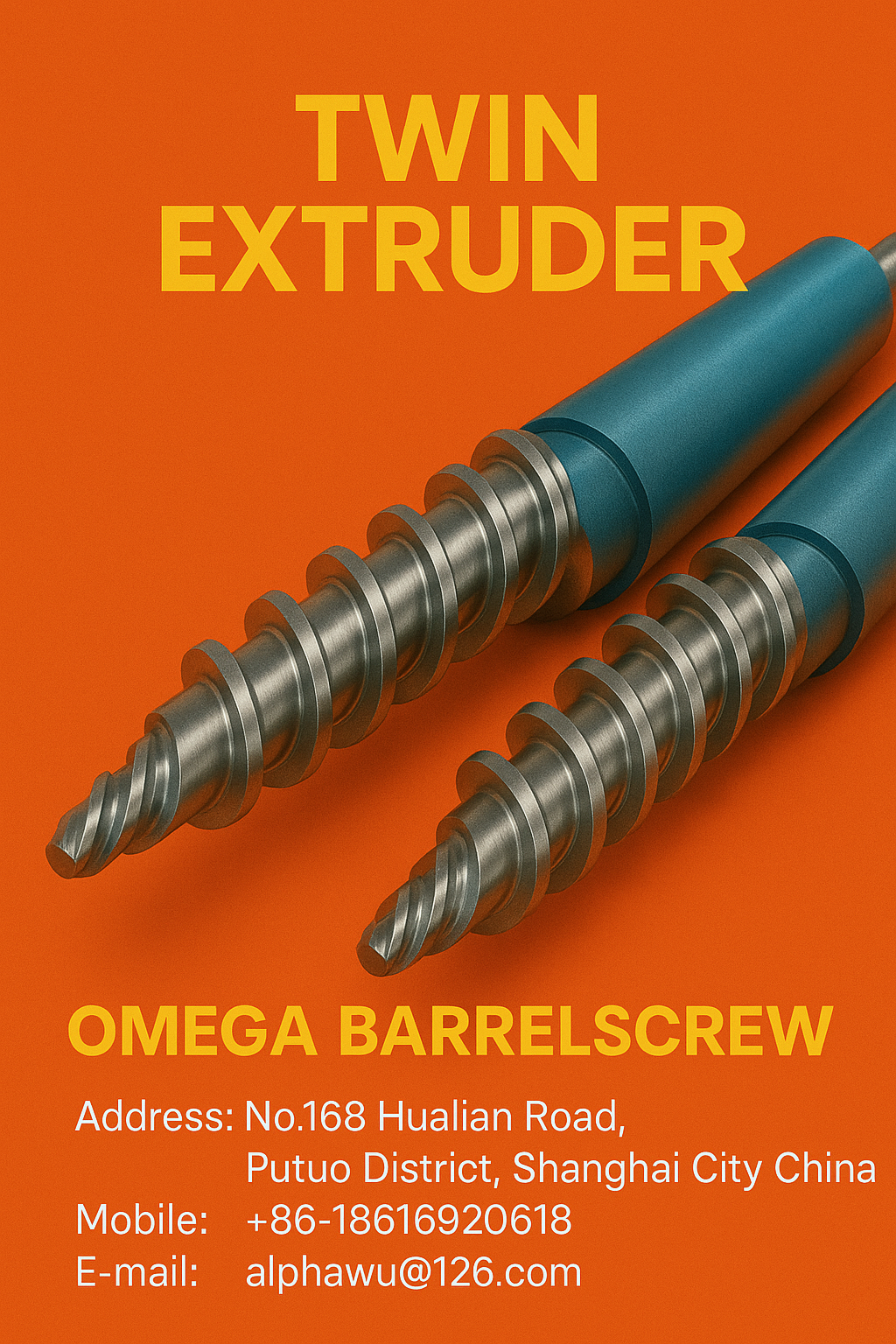

At Omegabarrelscrew, we manufacture top class-quality twin extruder components designed to supply superior performance, lengthy service existence, and reliable output across industries.

What Is a Twin Extruder?

A dual extruder consists of screws housed internal a barrel. These screws may be co-rotating or counter-rotating, relying at the application. The synchronized screw motion improves fabric conveying, melting, and mixing, making twin extruders best for processing complicated formulations.

Twin extruders are usually used for compounding, recycling, masterbatch manufacturing, % processing, and food extrusion. Their design guarantees uniform temperature distribution and high-quality material homogeneity.

Types of Twin Extruders

Co-Rotating Twin Extruder

In this kind, both screws rotate inside the same route. Co-rotating twin extruders are extensively used for compounding and mixing due to the fact they provide fantastic shear control and dispersion.

Counter-Rotating Twin Extruder

Right here, the screws rotate in opposite directions. This design is good for inflexible p.C processing, profile extrusion, and packages requiring gentle material dealing with.

Key Advantages of Twin Extruders

Twin extruders offer several blessings over traditional extrusion structures:

Superior mixing and mixing efficiency

Higher manufacturing output

Steady product quality

Better temperature and pressure manage

Green processing of warmth-touchy substances

Those benefits make twin extruders a favored preference for manufacturers looking for precision and productiveness.

Twin Extruder Components by Omegabarrelscrew

At Omegabarrelscrew, we specialise in manufacturing excessive-precision twin extruder barrels, screws, and screw factors. Our additives are engineered the use of superior metallurgy and wear-resistant substances to withstand extreme working situations.

We focus on:

Excessive wear and corrosion resistance

Correct machining for best screw-barrel alignment

Custom designs based totally on application desires

Prolonged service life with reduced upkeep

Our dual extruder answers assist producers enhance performance whilst decreasing downtime and operational costs.

Applications of Twin Extruders

Dual extruders are used in a extensive variety of industries, including:

Plastic compounding and recycling

P.C pipes, profiles, and sheets

Masterbatch and shade concentrates

Meals and feed processing

Pharmaceutical and chemical industries

Their flexibility makes them appropriate for each trendy and custom designed manufacturing approaches.

Why Choose Omegabarrelscrew?

Deciding on Omegabarrelscrew approach partnering with a depended on producer devoted to first-rate, innovation, and customer pride. Our dual extruder components are designed to meet global standards and deliver dependable overall performance in each software.

With advanced production centers and technical knowledge, Omegabarrelscrew maintains to assist industries global with durable and efficient extrusion solutions.

Leave a Reply